Cobots in Shipping Industry – Major Technological Innovations!

Posted On

Posted On

Why Cobots Are Introduced In Shipping Industry ?

Robotic systems and automated technology are occupying the significant portion in most of the manufacturing and shipbuilding industries. It has become a common sight to see cobots performing blasting, welding, heavy lifting, and various other tasks which are assisting in managing the lap shortage at shipyards. Moreover, it is better for human workers to remain away from such tasks as these tasks are thankless and dangerous.

The shipbuilding industry mostly depends on a large number of laborers who are skilled and professional. They hire employees who are willing to work for long hours and perform specific demanding tasks like painting, cutting, and welding to launch large vessels. Several shipbuilders have become famous by utilizing the talents of these workers. Such professionals are employed in most competitive shipbuilding countries like China, Japan, and South Korea.

The shipbuilding industry mostly depends on a large number of laborers who are skilled and professional. They hire employees who are willing to work for long hours and perform specific demanding tasks like painting, cutting, and welding to launch large vessels. Several shipbuilders have become famous by utilizing the talents of these workers. Such professionals are employed in most competitive shipbuilding countries like China, Japan, and South Korea.

Recently, the workforce of the industry has been affected by the global level. There has been a reduced occurrence of shipbuilding in several countries.

Natalie Desty, who is a marine recruitment expert, commented that industries such as oil and gas, construction, and nuclear are attracting a large number of employees who are marine qualified. He added that they are losing numerous trained employees from the marine industry to various other industries.

Cobots Plug The Employee Gap

Labor shortage continues, and it has a chance to dry up completely. The shipyard brawl for efficient professionals in the present highly competitive global market. Moreover, shipbuilders are highly dependent on various kinds of automation and also maintain their old strategies.

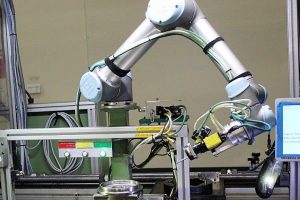

The labor demand is seen in all kinds of heavy industries; it is not only in the shipbuilding industry. Due to economic austerity or labor shortages, employers are getting to know the importance of cobots. It is the best driver of efficiency. Cobots helps human workers by performing dangerous and monotonous tasks.

As robots are helping to manage the labor loss in various manners in heavy industries, the rise in cobots use has become a trend all over the world. As per the research conducted by a top research company in February 2013, it has been found that there are more than one million industrial robots presently in employment. It has even created three million jobs and has chances of creating an extra million jobs in the forthcoming years.

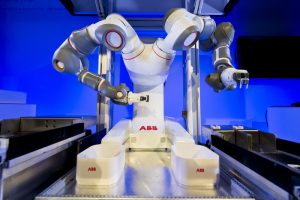

The growth is mainly due to the rapid implementation of progressive automation technologies in several industrializing countries like Brazil and China. Moreover, shipyards are playing an essential part in this automation trend. Shipyards located in Brazil are rapidly automating to cater to offshore and marine industry production requirement and to report skills that are in demand. One of the largest shipbuilding companies in South Korea is Geoje Shipyard. It has the top dock turnover rate in the world. It has been launching about 30 ships in a year. The efficiency of the shipyard is mainly because of the robotic production processes. It has been said that cobotic systems perform almost 68% of the processes.

Some of the intelligent systems employed at the facility are pipe cleaning and inspection robots and also units for welding. It is said to be the first shipbuilding company that depends on cobots for various operations. Check More info about how cobots fill a gap and create meaningful jobs.

Cobots And Technology Transfer

The utilization of cobots in the shipbuilding industry is expanding year by year. Technology like artificial intelligence and sensor systems are getting complicated. The industry is slowly customizing automation technology to utilize its efficiency for shipyard operations. Technology transfer and global collaboration is the main trend for fast digitizing shipyards. The developing companies need to expand the utilization of advanced cobots systems all through the word.

and sensor systems are getting complicated. The industry is slowly customizing automation technology to utilize its efficiency for shipyard operations. Technology transfer and global collaboration is the main trend for fast digitizing shipyards. The developing companies need to expand the utilization of advanced cobots systems all through the word.

The general development of global cobots technology is also resulting in the interface and design improvements. This way, the automated systems can be operated safely with no or less expertise. Moreover, it also motivates the prevalence of cobots to shipyards of different levels and sizes. Some of the main benefits of cobots include it does not require complicated programming codes and operator do not have to monitor it or assign tasks manually. It is possible for the operator to control around six robots at one time. If it requires service or fails, it goes to the service position. After the service, it can restart and return back to work. The customers can save a lot of expenses they spend on staff training. It is simple to monitor and control the cobot.